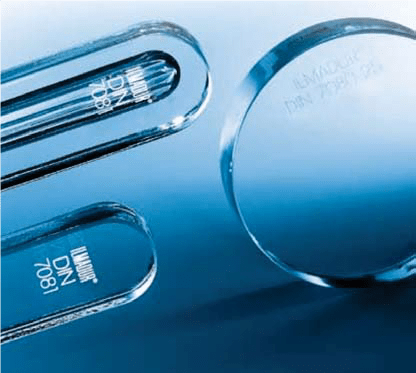

Borosilicate Gauge glasses

DESCRIPTION

Gauge glasses have high mechanical strength and are exceptionally resistant to alkalis, acids and boiler water (within the service limitation). Our glass testing laboratory carries out continuously quality control tests: purity of glass, flaws in glass, dimensional accuracy, etc. This ensures the high quality standard of gauge glasses.

TYPE

REFLEX GLASSES

APPLICATIONS

TRANSPARENT GLASSES

Transparent glasses are also manufactured from “extra-hard” borosilicate glass. The surfaces on both sides are finely ground and polished to ensure optimal transparency.

APPLICATIONS

In steam service above 35 bar and with media with a high pHvalue. transparent glasses must be protected by a mica shield on the side facing the medium chamber. Transparent glasses should always be chosen for contaminated, viscous or corrosive media. Within the given service limitations they may be used for all media except steam at pressures up to 340 bar or temperatures up to 400 °C.

TECHNICAL SPECIFICATION

MECHANICAL PROPERTIES

Compressive prestress

Standard:150 N/mm2 High Pressure:180 N/mm2

Standard:80 N/mm2 High Pressure:100 N/mm2

THERMAL PROPERTIES AND SERVICE CONDITIONS

Max. service temperature: 300 °C

Unprotected level gauge glasses: 35 bar at 243 °C

Transparent level gauge glasses protected with mica:103 bar at 320 °C

Transparent level gauge glasses in contact with media without significant

glass corrosion: 180 bar at 400 °C

High Pressure transparent level gauge glasses: 415 bar at 35 °C

Thermal shock resistance: ΔTmin. 265 K

FINISHES

Surfaces: polished

Lateral Surfaces: plain moulded or ground (for manufactoring reasons beveled 1,5°)

Edges: beveled at an angle of 30° or 45°

Width of sealing surface: min. 5 mm for 30 mm wide level gauge glasses, min. 6 mm for 34 mm wide level gauge glasses

TYPE

CIRCULAR SIGHT GLASSES

Circular glasses are also manufactured from “extra-hard” borosilicate glass. Borosilicate glass, thermally pre- stressed, optically tested, properties as laid down in DIN and OeNORM. Extract from the OeNORM: Chemical pre-stressing of glasses is not permissible. For safety reasons soda-lime glasses may not be used.

APPLICATIONS

Transition temperature: TG=550 °C,

Temperature resistance: Suitable for temperatures from – 273 °C To + 300 °C, size 31.75/12.7 up to 356 °C.

TECHNICAL SPECIFICATION

MECHANICAL PROPERTIES

Tensile bending strength: ≥160 N/mm2

Compressive prestress: ≥100N/mm2

THERMAL PROPERTIES AND SER VICE CONDITIONS

Max. service temperature: 300 °C

Thermal shock resistance: Δ T min. 265 K

FINISHES

Surfaces: polished

Lateral Surfaces: plain moulded or ground (for manufactoring reasons beveled 1,5°)

Edges: beveled