Flange Insulation Kits

DESCRIPTION

“Flange Insulation Kits” are designed to ensure electric insulation and to combat the effects of corrosion often found in flanged pipe systems.

By eliminating metal-to-metal contact, static current is halted to prevent corrosion and aid in the cathodic protection of the piping system.

They can be used to control stray electric currents in piping at oil, gas, water, refinery and chemical plants in order to increase the effectiveness of cathodic protection systems.

Experience has shown that the cathodic protection, together with a high grade passive corrosion protection by application of coating on the pipeline, provides a most efficient and economical solution.

Insulation sets are used to limit corrosion in pipeline systems. Where dissimilar metals are present, the sets remove the possibility of the system acting as a galvanic cell and reduce the risk of galvanic corrosion of the pipework.

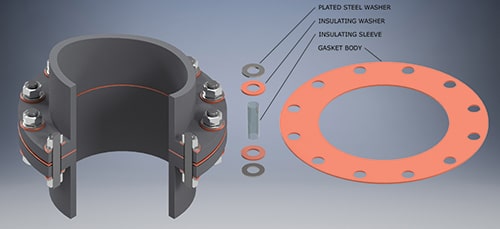

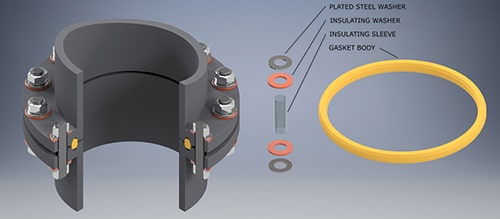

Insulation sets are also used to isolate cathodically protected piping systems where they prevent the flow of electro-static charge. Each flange insulation set comprises one central flat or oval section gasket, one insulation sleeve per bolt and two insulating and two plated steel washers per bolt. The sets are individually packed and clearly labelled with the flange rating, size, type and material combination.

PROPERTIES OF STANDARD INSULATION MATERIAL

| Gasket, washer, sleeve | Insulating Sleeve | Insulating Washer | Gasket | Component | |

|---|---|---|---|---|---|

| Glass reinforced epoxy resin, G10 | *Mylar | Phenolic | *Reinforced Phenolic | ® Neoprene * Faced Phenolic | Material |

| 31.5 – 29.5 | 157.5 | 5.5 | 7.9 | 19.7 | Dielectric Strength (kV/mm) |

| 450 | – | – | 270 | 270 | Comp. Strength (N/mm2) |

| 450 | – | – | 155 | 155 | Flexural Strength (N/mm2) |

| 0.05 | 0.8 | 1.0 | 1.0 | 1.6 | (%) Water Absorption |

| – | 145 | 107 | 107 | 107 | Max. Operating temp. (˚C) |

Type F

– Where the extra security of full face isolation is required.

– For use in either a flat face or raised face flanges.

– Manufactured from material with high dielectric strength to ensure minimum electrical contact between flanges.

Max. temperature: 100oC

Max. pressure: 40bar

Max. dielectric strength: 500 Volt/mm

Type D

– Applications: Oil and Hydrocarbons where flange insulation is a requirement.

– For use in RTJ flange arrangements.

– Manufactured from material with high dielectric strength to ensure minimum electrical contact between flanges.

– Fabric reinforced phenolic resin without rubber coating

Max. temperature: 100oC

Max. pressure: 40bar

Max. dielectric strength: 200 Volt/mm

CONSTRUCTION

Reinforced Die formed Graphite Ring

Moulded from pure flexible graphite with reinforcement, the insert materials stainless steel foil or mesh etc. are available on request. To protect against oxidation, the stainless steel cap is necessary.

Die formed Graphite Ring with Corrosion Inhibitor

Corrosion inhibitor acts as a sacrificial anode to protect the valve stem and the stuffing box.

APPLICATION

It has all properties of expanded graphite, can bear violent alteration of temperature and pressure. It is ideal packing for valves and static seal in almost all applications. Can be used as stand-alone packing or in combination high carbon fiber antiextrusion packing rings, except when stems are severely damaged.

PARAMETER

| Valves | Agitators | Fans (Dry running) | |

|---|---|---|---|

| 800Bar | 50Bar | 10Bar | Pressure |

| 2m/s | 5m/s | 10m/s | Shaft speed |

| 1.2~1.75g/cm3 (Normal: 1.6g/cm3) | Density | ||

| -220~+550°C (+2800°C in non-oxidizing environment) | Temperature | ||

| 0~14 | PH range | ||

DIMENSIONS

As pre-pressed rings (full or split)

Straight cut and slanted cut on request.

Supply size: Min. cross section: 3mm

Max. diameter: 1000mm

For special profiles, rectangular, with inner- or outer bevel, with cap, please offer detailed drawing & sizes.

Graphite of nuclear grade (99.5%) on request.