O-RING

DESCRIPTION

O-rings is an efficient and economical sealing element for a wide range of static and dynamic applications. Inexpensive production methods and its ease of use have made the O-ring the most widely used seal.

A wide choice of elastomer materials for both standard and special applications allow the O-ring to be used to seal for all liquid and gaseous media.

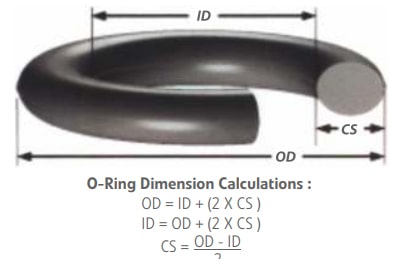

O-rings are produced in moulds and are characterized by their circular form with annular cross section. O-rings dimensions are defined by the inner diameter (ID) and the cross section (CS). The dimension of an O-ring can be easily calculated by a simple.

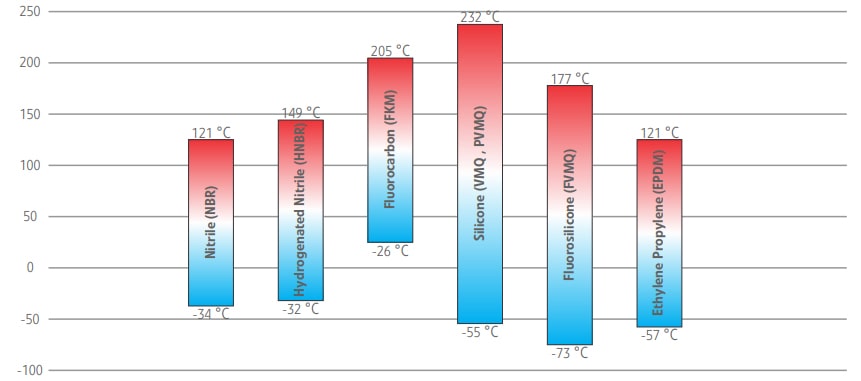

SERVICE TEMPERATURE RANGE CHART

This service temperature range is for reference only. In actual service environment, some specific compounds may not reach the maximum temperature as indicated in this chart. However, higher temperature may be attained if exposed is short or intermittent.

MATERIAL

ELASTOMER

| Recommended for Use | temp | Shore A Hardness | Material |

|---|---|---|---|

Petroleum oil & fluids, Diesel fuel & fuel oils, Cold water, Silicone oil & grease, Mineral oil & grease, Vegetable oil, HFA, HFB & HFC fluids | -34°C to 121°C | 70/90 | Nitrile (NBR) |

Diesel fuel & fuel oils Dilute acids & bases | -32°C to 149°C | 70 | Hydrogenated Nitrile (HNBR) |

Petroleum oils & fluids, Silicone greases & oil, Aliphatic hydrocarbons, Aromatic hydrocarbons, Fuels with methanol contents, Fuels, Cold water | -26°C to 205°C | 75/90 | Fluorocarbon (FKM) |

Animal & vegetable oil & grease, Fire-resistance hydraulic fluid, Ozone, aging & weather resistance, Engine & transmission oil | -55°C to 232°C | 70 | Silicone (VMQ , PVMQ) |

| Fuel & Aromatic mineral oil Engine & transmission oil | -73°C to 177°C | 70 | Fluorosilicone Rubber (FVMQ) |

Hot water, Many organic & inorganic, Cleaning agents, Soda & potassium alkalis, Many polar solvents, Glycol based brake fluids | -57°C to 121°C | 70/80 | Edthylene Propylene Rubber (EPDM) |

Mehrbodan has a full rage of rubber compounds to suit various temperature, pressure and chemical compatibility requirements. If your applications requires an alternte rubber compound , not listed , please consult a Mehrbodan Application Engineer or Sales Personal.

KALREZ

For demanading sealing applications when customers require the very best, Kalrez parts manufactured only by Dupont Performance Elastomers, are the elastomer seals of choice. Supplied in standard O-rings or custom shapes, Kalrez resists over 1,800 different chemicals while offering the high temperature stability of PTFE (327 C).

Back -up rings are used in conjunction with O-rings for both static and dynamic sealing sealing applications. They prevent extrusion of the O-ring when it is subjected to high pressures, or when the extrusion gaps are excessive.

Back-up rings are in stock and ready to supply in Nitrile and PTFE materials .

Quad-rings are four-lipped seals with a specially developed sealing profile that actually provides twice the number of sealing surfaces as O-ring. It’s provide lower friction than an O-ring and due to tis square ctoss section, it resists sporal twist.

Quad-rings are available in all standard O-ring size of American Standards AS568A, as well as sustom seais for unique applications.

30 SIZES OF O-RINGS IN A HANDY STORAGE CASE

This convenient O-Ring Kit contains 30 of the most popular sizes, for a total of more than 400 O-Rings, in one convenient Kit. It is ready to use and will give you easy access and storage to whatever size you need. The storage posts are clearly labeled to provide instant size identification. There is even a built in gauge to measure the size of the old O-Ring needing replacements . this Kit is available in either high performance Viton, Buna-N composition.

O-Rings Cords is used instead of an O-ring in certain cases. It is only applicable as a static seal. They are made from extruded strip, and the joints is either by vulcanization or an adhesive. ORing Cords are used for sealing on large flanges, covers on large containers etc.

O-ring Cord is available in Viton and Buna material.

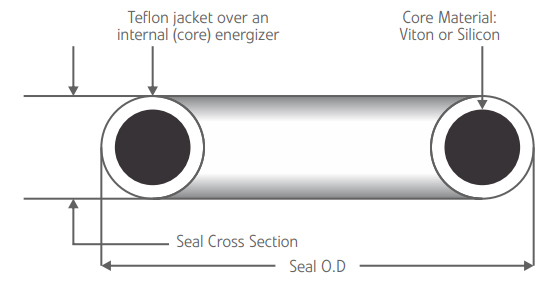

DESCRIPTION

Encapsulated O-rings are o-rings consisting of a seamless and uniform Teflon FEP/PFA encapsulation/jacket which completely encloses a core material of either silicone or Viton fluoroelastomer. The combination of these components creates an o-ring that is virtually chemically inert and compression set resistant for use in harsh sealing environments.

ENCAPSULATION O-RING MATERIALS

Encapsulation (Outer Jacked) :

FEP Teflon combines superb corrosion resistance, sealing integrity and an operating temperatures range of -450 to +400 F (267 to +205 C).

PFA Teflon, a fluorocarbon copolymer similar to FEP, also provides greatly improved mechanical and creep properties at higher operating temperatures: -450 to +500 F (-267 to +260 C).

Core Materials (Internal Energizer) :

Viton

Silicone

DIMENSION

| Smallest I.D MM | C / S MM | Smallest I.D MM | C / S MM |

|---|---|---|---|

| 18.00 | 4.00 | 7.20 | 1.78 |

| 25.00 | 4.50 | 7.20 | 2.00 |

| 25.00 | 5.00 | 9.19 | 2.40 |

| 25.00 | 5.33 | 9.19 | 2.62 |

| 27.94 | 5.58 | 12.29 | 2.79 |

| 27.94 | 5.70 | 12.29 | 2.92 |

| 27.94 | 6.00 | 12.92 | 3.00 |

| 27.94 Silicon 35.00 Viton | 6.30 | 12.92 | 3.53 |

| 27.94 Silicon 35.00 Viton | 6.99 | 18.00 | 3.80 |