GASKET SHEET GAMBIT AF-1000

MATERIAL

Gasket sheet GAMBIT AF-1000 is based on Kevlar® aramide fibres, mineral fibres, and fillers bound with NBR rubber-based binder; reinforced with galvanized steel mesh.

Designation according to DIN 28091-2: FA-AM1-ST

Kevlar® is a registered trademark of E. I. du Pont de Nemours and Company or its affiliates.

General properties and applications

Used in high temperature flange joints, in systems with high fluctuations in pressure and medium flow rate.

Features high mechanical resistance. Can be used in automotive industry. It is not recommended with acids and bases. When working with steam mind using suitable mounting clamps. Water, steam, kerosene, gasoline, fuel, and oil resistant.

| Dimensions | |||

|---|---|---|---|

| Standard thicknesses of sheets | mm | 0.8 , 1.0 | ±0.1 |

| 1.5 , 2 , 2.5 , 3 , 4 , 5 | ±10% | ||

| 6 | ±10% | ||

| Standard dimensions of sheets | mm | 1500×1500 | ±10 |

| Maximum working conditions | ||

|---|---|---|

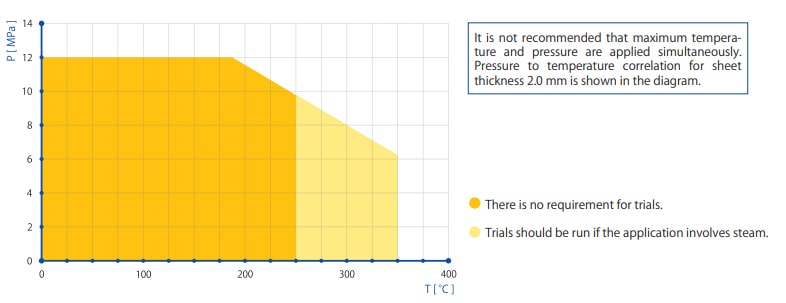

| Peak temperature | ⁰C | 420 |

| Temperature under continuous operation | ⁰C | 350 |

| Temperature under continuous operation with steam | ⁰C | 250 |

| Pressure | Mpa | 12 |

| Physical and chemical properties | ||||

|---|---|---|---|---|

| FA-AMZ-O | DIN 28091-2 | |||

| Density | ±5% | g/cm3 | 2.2 – 2.45 | DIN 28090-2 |

| Compressibility | min | % | 9 | ASTM F36 |

| Elastic recovery | min | % | 50 | ASTM F36 |

| Residual stresses 50 MPa/16 h/300 °C/ | min | Mpa | 32 | DIN 52913 |

| Residual stresses 50 MPa/16 h/175 °C/ | min | Mpa | 35 | DIN 52913 |

| INCREASE IN THICKNESS | ||||

| Oil IRM 903 150 °C/5 h | max | % | 8 | ASTM F146 |

| Model fuel B 20 °C/5 h | max | % | 7 | ASTM F146 |

| Kerosene 20 °C/24 h | max | % | 6 | ASTM F146 |

| Colour Graphite | ||||