SPIRAL WOUND GASKETS

DESCRIPTION

Spiral wound gaskets are manufactured by spirally winding V shaped metal strip and a strip of non-metallic filler material. Spiral wound gaskets can be reinforced by an outer centering ring and/or inner retaining ring. Spiral wound gaskets can be used for sealing flange joints, manhole and hand hole covers, tube covers, boilers, heat exchangers, pressure vessels, pumps, compressors and valves.

SHAPE AND CONSTRUCTION

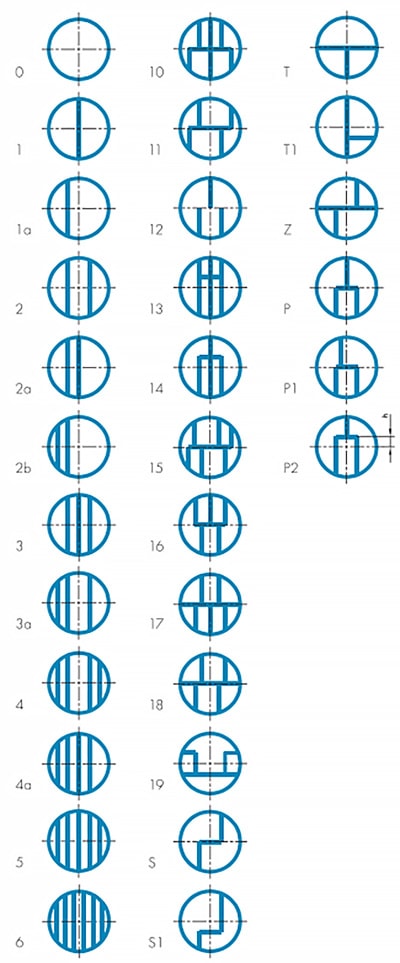

Spiral wound gaskets are usually of circular shape, however we can produce them in other shapes such as: oval, rectangular with round corners,etc. Ourstandard production program comprises a range of spiral wound gaskets with inner diameters of 10 mm to 3000 mm and a nominal thickness of 3.2mm, 4.5mm and 6.5mm. Spiral wound gaskets of non-standard dimensions and shapes, and larger diameters are available on request.

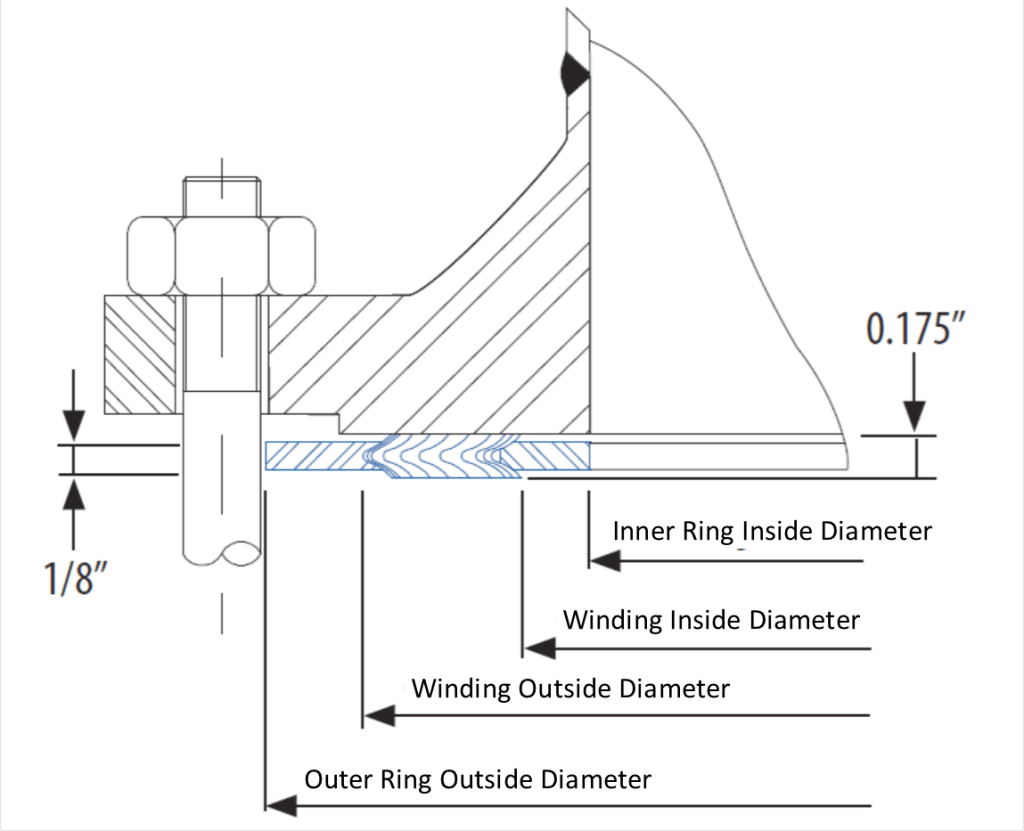

CONSTRUCTION

MATERIALS FOR SPIRAL WOUND GASKETS METALLIC STRIP

Holds the filler. Standard thickness of the metallic strip is 0.2mm (0.18 inch). Materials for metallic strip are as below table:

| MATERIAL FOR METALLIC STRIP | |

|---|---|

| ASTM | DIN Material No. |

| AISI 304 | 1.4301 |

| AISI 316 , 316 L | 1.4404 , 1.440 |

| AISI 321 | 1.4541 |

| AISI 316 Ti | 1.4571 |

| Monel (NiCu30Fe) | 2.4360 |

CENTERING RING

Centering ring controls the compression and holds the gasket centrally within the bolt circle. The centering ring does not come into direct contact with contained fluid. It is normally made of carbon steel and electro plated or painted to avoid corrosion. Other materials are available on request.

INNER RING

The inner retaining ring increases the axial rigidity and resilience of the gasket. Inner ring is used to avoid excessive compression due to high seating stress in high pressure service and it is also used to reduce turbulence in the flange area. It is normally made of the same material as the metallic strip.

DIMENSIONS SIZES

The dimensions of the standard SWG meet the ASME, BS and EN (DIN) standards. Limitations for dimensions are shown in following table:

| LIMITATIONS FOR MANUFACTURING DIMENSIONS | |||

|---|---|---|---|

| Maximum width – bs [mm] | Max diameter d3 [mm] | Thickness [mm] | |

| PTFE | Graphite | ||

| 13 | 16 | 300 | 2.5 |

| 19 | 22 | 700 | 3.2 |

| 24 | 30 | 1500 | 4.5 |

| 24 | 35 | 3000 | 6.5 |

| 24 | 30 | 3000 | 7.2 |

These limitations are general and can vary according to the specia customer requirements

Thickness

Tolerances

The tolerances of the gasket diameters stimulated by ASME B 16.20 and EN 1514-2 standards.

The gaskets designed for non-standard flanges meet the recommendations by the ASME B 16.20.

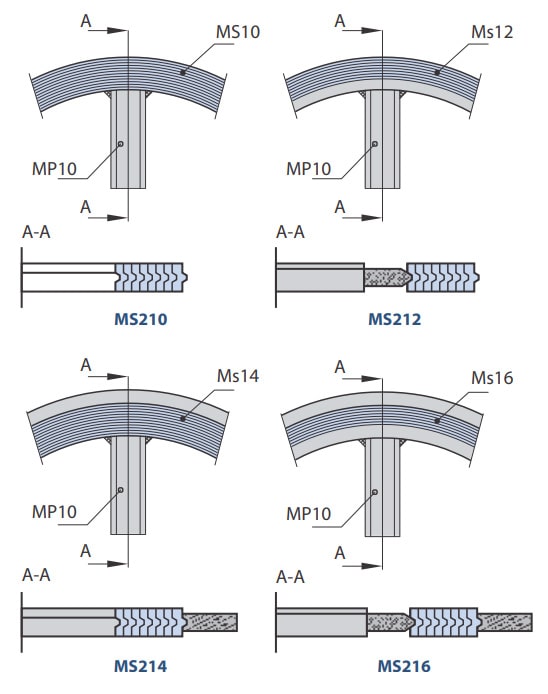

DESCRIPTION

The spiral wound gaskets for MS10, MS12, MSU or MS16 type can be manufactured with one or more metal jacketed bars (profile MP10) in different shapes shown in drawing. Metaljacketed bars are welded and made of the same material as the spiral windings. The standard thicknesses are 3.2mm, 4.5mm, 6.5mm and 7.2mm. Below table shows the max dimensions for these SWG gaskets:

| MAX DI MENSIONS | |

|---|---|

| Max diameter [mm] | Thickness [mm] |

| 750 | 3.2 |

| 1500 | 4.5 |

| 2200 | 6.5 |

| 2500 | 7.2 |