Metal-jacketed gaskets

CONSTRUCTION

Metal-jacketed gaskets are particularly suitable for sealing flat surfaces of heat exchangers, gas pipes, cast iron flanges, autoclaves and similar. The heat exchanger gaskets come in a wide range of types including single or double jacketed, corrugated, plain metal, soft and many others.

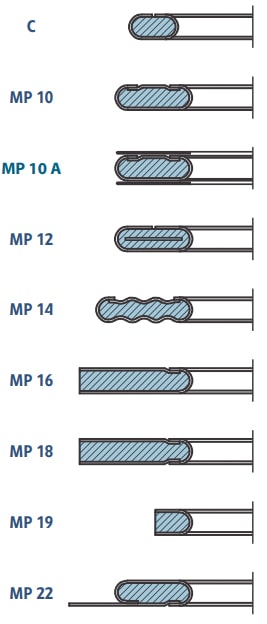

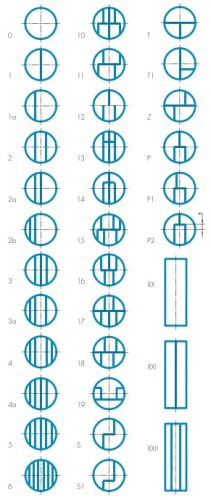

SHAPE AND CONSTRUCTION

MATERIALS FOR HEAT EXCHANGER GASKETS METALLIC JACKET

Selection of the jacket material depends on operating conditions. Materials for metallic jacket are as below:

| .DIN MATERIAL NO | ASTM | MATERIAL |

|---|---|---|

| 1.0333 | Soft Iron (CS) | Low Carbon Steel |

| 1.4301 | ASISI 304 | Stainless Steel |

| 1.4401 , 1.4404 | AISI 316, 316L | Stainless Steel |

| 1.4541 | AISI 321 | Stainless Steel |

| 1.4571 | AISI 316 Ti | Stainless Steel |

| 2.4360 | Alloy 400 | Monel(NiCu30Fe) |

| 2.0090 | Copper | Copper |

| 2.0321 | Brass Ms 63 | Brass |

| 3.7025 | B 348 Gr. 1 | Titanium |

– Metallic jacket is normally 0.4mm thick

– Other alloys available on request

FILLER

The standard filler material is flexible graphite. Other fillers like ceramic, mineral or other can also be used.

SIZES

The metal jacketed gaskets come in sizes according to EN 1514-4 and ASME B 16.20. Below table shows standard dimensions for these gaskets:

| STANDARD DIMENSIONS | |

|---|---|

| 2 -12 mm | Gasket thickness |

| 10 , 13 and 16 mm | Gasket width |

| 8 , 10 and 13 mm | Bar width |

TOLERANCES

Thetolerances of metal jacketed gaskets meet ASME B 16.20 and EN 1514-4. Manufacturing tolerances are as follows:

| MANUFACTURIN TOLERANCES | ||

|---|---|---|

| Diameter tolerance (mm) | Gasket Inside Diameter (mm) | |

| Outside diameter | Inside diameter | |

| +0.0 ; -0.8 | +0.8 ; -0.0 | Up to 150 |

| +0.0 ; -1.6 | +1.6 ; -0.0 | from 150 to 1500 |

| +0.0 ; -2.4 | +2.4 ; -0.0 | 1500 or greater |

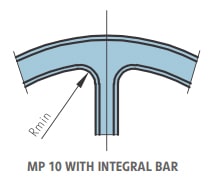

Double jacketed gaskets for heat exchangers are manufactured with integrated bars. There is a radius between bars and an internal diameter of the gasket. The values of the radius for the most commonly used metals and alloys are shown in the following table. If a radius is less than R min, the material can crack, reducing the sealing properties of the gaskets. Gasket materials can be seen in below table:

| GASKET MATERIALS and R min | |

|---|---|

| R min | Gasket material |

| 8 mm | Copper |

| 8 mm | Soft iron (CS) |

| 10 mm | Brass, Monel |

| 10 mm | Stainless steel |